History

Discover our journey that we are on since 2010.

2010

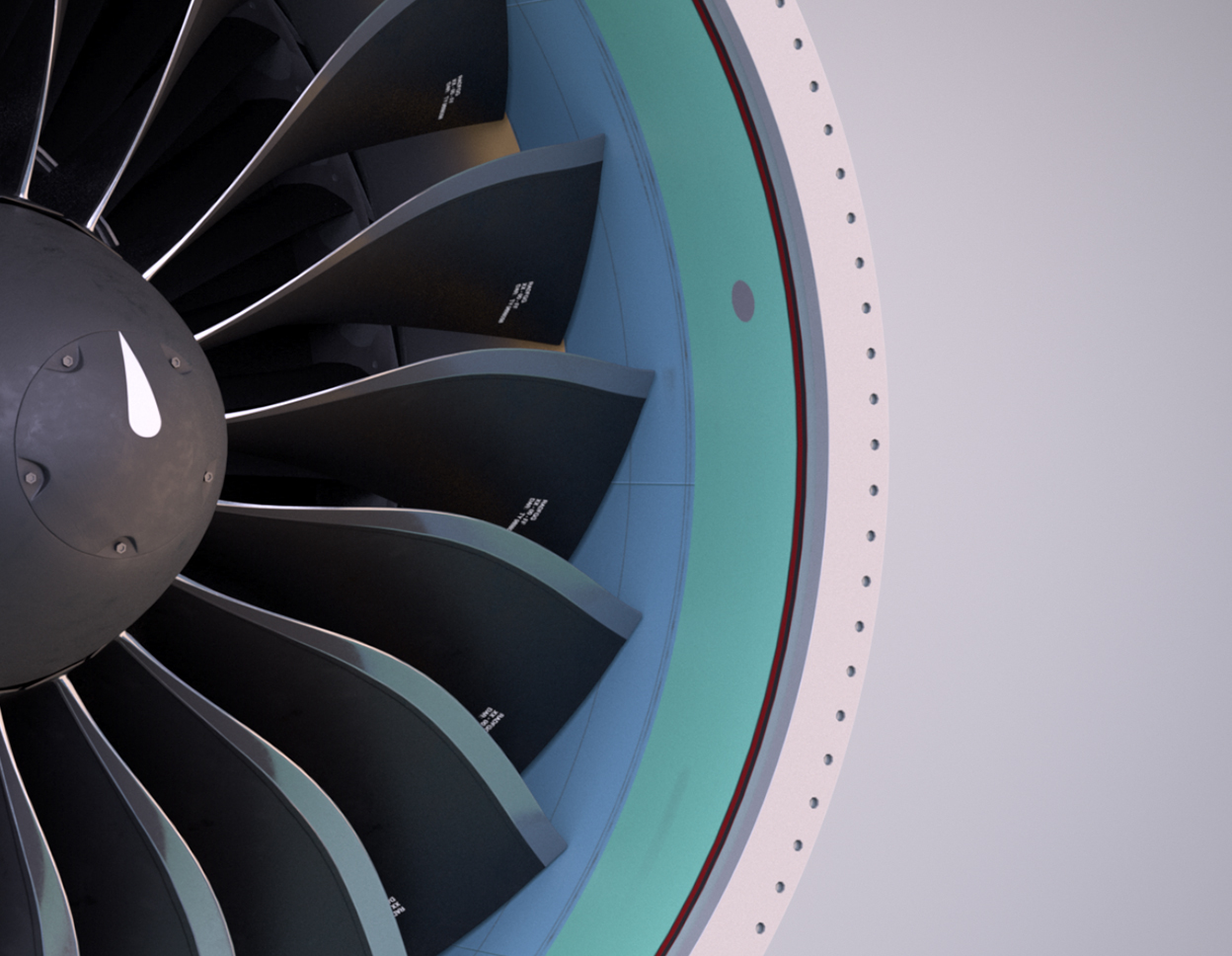

The foundations of Kale Pratt & Whitney were laid as a result of the joint venture between Kale Group and Pratt & Whitney, one of the leading organizations of the world in aviation sector. A license was obtained on the same year for manufacturing parts for F135, which is the engine of F35, the most advanced fighter aircraft in the world.

2011

Groundbreaking ceremony was held for the construction of the plant at İzmir Aegean Free Zone. AS9100 Quality Management System certificate was obtained, which is one of the main requirements for aviation sector.

2012

As the plant construction continued, the manufacturing activities were started at a temporary premise with the main personnel.

FAI (First article inspection) was completed and the first shipment was made on the same year.

2013

The product portfolio was extended, FAIs were completed and the transition into mass production began.

The construction of the plant was completed. It had an indoors area of 14.000 m2 in a total area of 100.000 m2.

2014

After the completion of the plant construction, a joyous ceremony was held, which was attended by the 11th President of the Republic of Turkey, Mr. Abdullah Gül.

New FAI productions and mass productions were adapted to the new plant.

Training encompassing the entire personnel was expedited, increasing the number of qualified employees.

2015

The first internal audits, conducted by United Technologies Corporation and Kale Group, were completed successfully.

Configurations were completed for many special processes that are important in aviation sector such as Hot Form, Electron Beam Welding Machine, Plasma Spray, Chemical Lines and certificates were obtained.

FAI production with the highest unit number of all time was achieved with 225 parts and this was a significant success.

2016

A MLA license was obtained for SME Flap, which is one of the critical parts of the F-35 aircraft engine that is manufactured as part of JSF project, and the production started.

The ERP system covering all of our plant processes was optimized, ensuring the first step of the big data analysis pool.

Machining parts of the NGPF series, which is the new generation aircraft engine by Pratt & Whitney, was included in the product portfolio.

2017

The number of employees increased in parallel to the number of obtained projects and reached a number of 322 employees in a short time.

In parallel to increase in growth, the total turnover increased 2,5 times compared to previous year.

Operational excellency was expedited for our production processes.

2018

Machining capability investment was increased in regards to the rise in NGPF engine parts.

A transition was made into Value Stream Organization which integrates all operational departments in order to increase the production efficiency.

The total turnover increased 2 times compared to previous year.

2019

ISO 14001 Environmental Management System, ISO 45001 Occupational Health and Safety Management System documents were renewed.

NIST 800-171 requirements were met for complying with Information Security Management and ISO 27001 Information Security Management System document was obtained.

“Gold-rated Supplier” audit conducted by Pratt & Whitney was successfully completed and the first steps were taken to obtain this title.

Our number of qualified employees reached nearly 500.

Our suggestion system named “Opinions from Kale”, which allows 100% employee participation, has been implemented.

In parallel to raise in growth, the total indoors area was increased to 16.250 m2.

2020

Awarded

Raytheon Technologies – Platinum Supplier award by Raytheon Technologies.

2022

NIST

800-171 Information Security Self-Assessment study was carried out.

Sustainability

Projects were initiated.

Certificates

were awarded by obtaining a successful result from NADCAP audits.

2023

ISO

50001 Energy Management System certificate was obtained.

In the

research it carried out to determine the companies that make their employees

the most happy in the Aegean Region during the Great Place to Work process, it

ranked 4th in the 250-499 employee category and was awarded the Best Employers

of the Aegean in 2023.